Many people in the mining industry have heard stories about how the ore was ‘harder than expected’ or the mill is ‘not achieving design throughput’. How can this problem be avoided? It comes down to three main factors: varying hardness across the samples, using different testing methods to check for unexpected behaviour, and considering the effect of feed size.

SRK can help determine how these three factors affect the performance of a particular grinding circuit.

A number of comminution (size reduction) tests are available and each one is focused on a particular piece of equipment and size range. Hardness depends on the application, and measuring resistance to impact breakage is very different from measuring resistance to abrasion. The number of samples required depends on how the results vary across the deposit. It is well worth conducting additional hardness tests to better define a particularly difficult part of the orebody rather than hoping it doesn’t exist.

In determining sample size requirements, nothing beats measuring hardness on the actual size of material to be processed. Keep some full or half core around for hardness testwork; it will be broken but not destroyed and can be used later. While a single measure of hardness is useful, it is always best to double check a number of samples using different methods.

For semi-autogenous grinding (SAG) mills, there are two basic forms of testing: single particle breakage and tumbling tests designed to recreate the actual mill environment. For high pressure grinding rolls and regrind mill sizing, a specific test designed for that piece of equipment is best.

Basically, the test results estimate the specific energy requirements for crushing, SAG milling and ball milling. Using a power modelling approach, different mill sizes are selected to meet the power requirements that achieve the design tonnage.

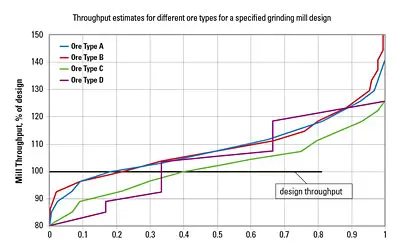

In the figure below, the range of expected throughput for different ore types are plotted for a fixed grinding circuit; each ore type can process between 80% and 120% of the design throughput. An alternate power model was used to estimate mill throughput using the same mill sizes. In this case, a greater variation in throughput was predicted for the samples using the alternate power model – or was more sensitive to the test results. Coarser or finer mill feed size can result in a ±15% swing in tonnage for the same hardness of material.